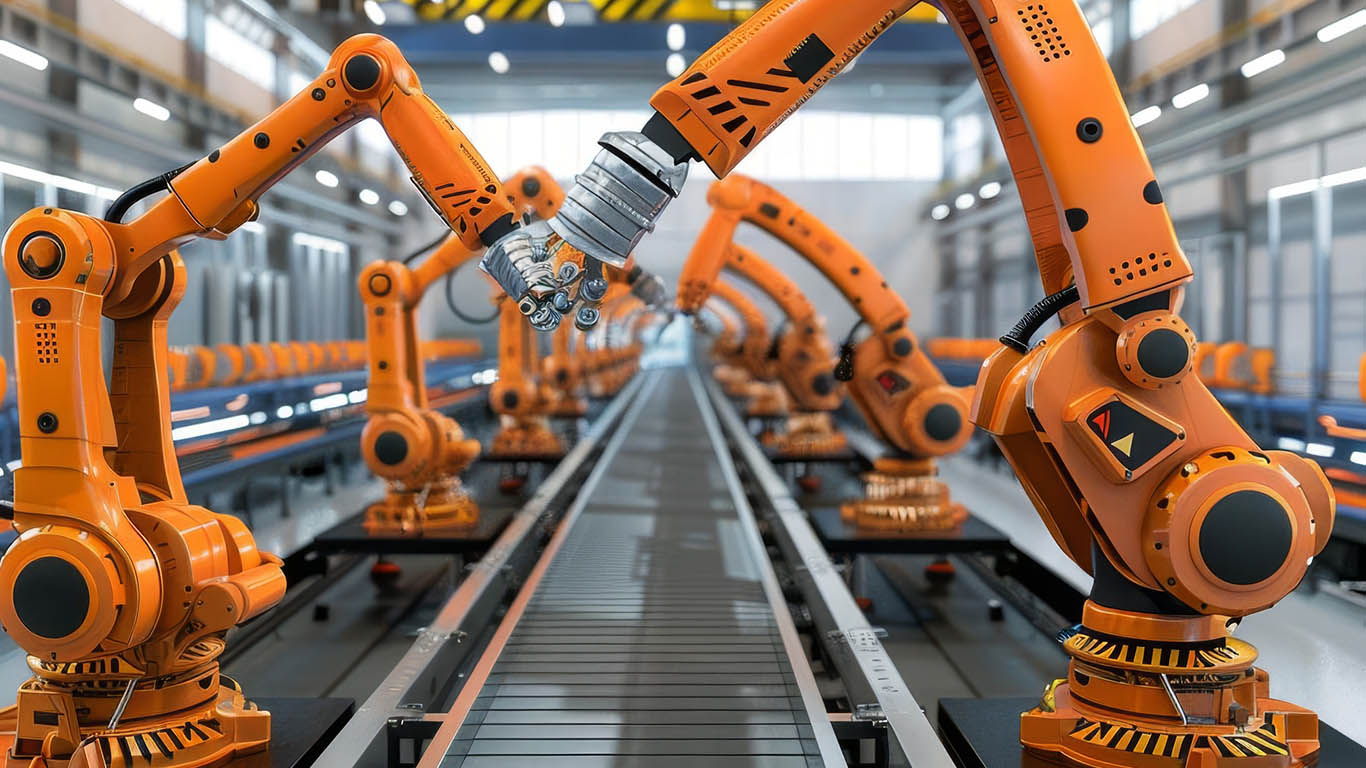

The moment that you transmit an input from the machines and sensors to the cloud, it creates an unavoidable delay in decision making. Nobody wants to make a decision in a fast-paced environment when there is more delay between a piece of critical information being made available in the cloud, as opposed to closer to the source. In a domain where milliseconds and kilometers can mean the difference in getting the right order out the door, edge computing is fast becoming an indispensable item in any smart factory. Smart factories are abundant in devices that produce large amounts of data every millisecond from IoT enabled machines, and real-time monitoring systems, to PLC controllers, SCADA systems, predictive maintenance sensors, etc. In the past, all this would be sent to a centralized data center/cloud before gaining any insights. With edge computing, insights can be made in real-time allowing for quicker, smarter decisions which improve machine efficiency and alleviates large amounts of congestion on networks. The advantages of edge computing for manufacturing are technical, and could be significantly beneficial for the business as well: Real-Time Decisions: Edge devices process data locally in real-time allowing operators to make on-the-fly touch-ups on the production line, based on the insights given by edge devices. Reduced Latency: Instead of dealing with waiting for data to go to the cloud or centralized device then back, edge devices process data locally so there will always be less variability in latency against using a cloud service. More Reliable Operation: In situations where network connectivity becomes intermittent to poor, the edge systems can maintain operation efficiently and more reliably. Improved Security: In the sense that sensitive data can stay within the four walls of the factory and not be exposed outside of the factory environment. Better Bandwidth Usage: The edge devices will only send the best data (useful data) to the cloud or centralized computing service, thus cutting unnecessary costs on cloud services as well as streamlining the analytics. For example, a packaging plant deployed edge-enabled AI cameras that were able to take in product quality. These cameras were able to pick up small defects in real-time and initiate a monitored change allowing for the reduction of waste and rework. We see another example with predictive maintenance. With AI deployed at the edge, a factory can also monitor vibration, temperature, and load from a motor or pump device and immediately recognize an unusual pattern. Instead of waiting for a centralized system to warn them of abnormal operation, edge AI can generate a warning in real time — stopping possible downtime before it begins. Edge computing is absolutely essential to Industry 4.0 type initiatives. As manufacturers deploy smart sensors, digital twins, robotic automation, and machine learning at the edge, they are creating an ecosystem that is more autonomous, more efficient, and more responsive to disruption or change. Whether it involves running a high-speed assembly line or coordinating an intricate set of industrial robots, edge technologies provide agility at the most needed level — at the operation layer. Certainly, there are challenges. Integrating edge devices and apps into existing or legacy systems may be challenging and edge security also deserves consideration. But ultimately, the long-term benefits — like improved OEE (Overall Equipment Effectiveness), faster trouble-shooting capabilities, and scalable infrastructure — ultimately represent a strategic necessity to modern industrial landscapes. Even as smart factories are continually evolving, industrial edge computing is quickly transitioning from its supporting technology status to being the backbone of intelligent manufacturing. It completes a full loop from raw item to finished product, storing information derived from the edge, back into the supply chain to optimize future processes and outcomes.

Didn't Find What You Were Looking For?

Let Us Help You