Control Algorithms: Vector Control vs Direct Torque Control (DTC)

ACS580 – Stable and Practical Control

ACS580 uses sensor less vector control combined with integrated PID functionality. This control approach adjusts motor voltage and frequency smoothly to maintain stable speed and torque under normal load variations.

It performs particularly well in applications such as pumps, fans, compressors, and conveyors where reliability, ease of setup, and predictable performance are key priorities.

ACS880 – Direct Torque Control (DTC)

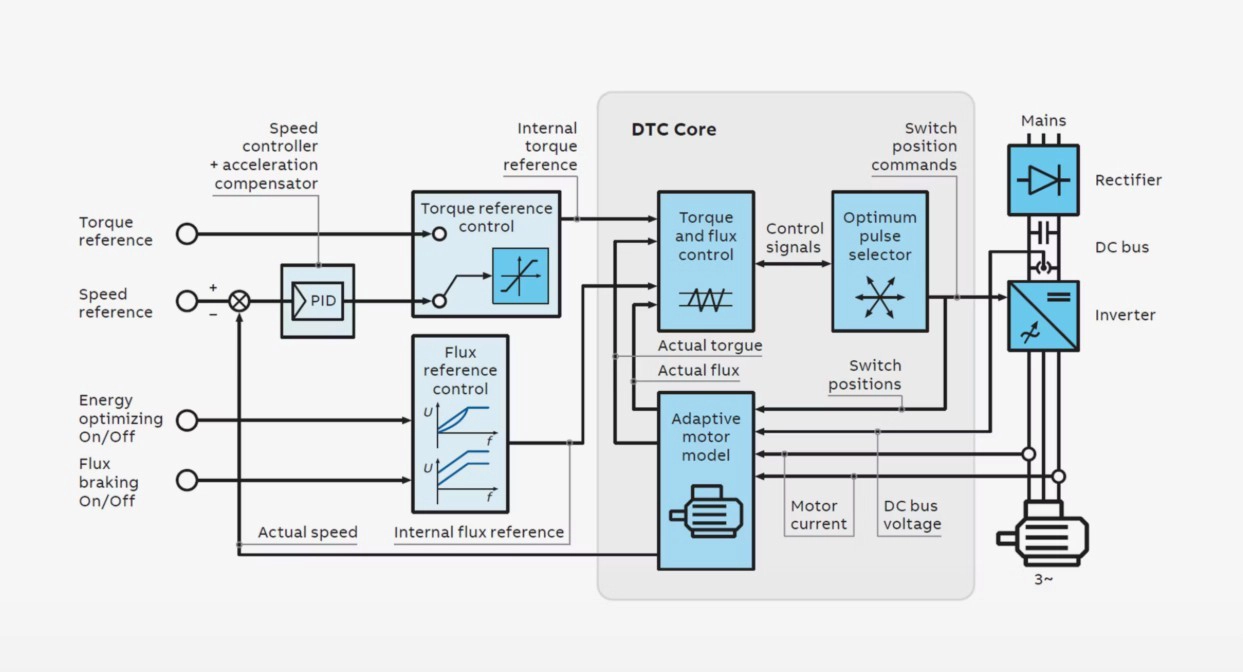

ACS880 is equipped with ABB’s Direct Torque Control (DTC), which directly controls motor torque and flux in real time. Unlike traditional vector control, DTC eliminates the need for a modulator, resulting in much faster torque response. This provides:

Figure 2: ABB Direct Torque Control (DTC) architecture showing torque and flux control without encoder feedback.

- High torque accuracy even at low speeds

- Faster response to sudden load changes

- Reduced mechanical stress on motors and gearboxes

These advantages make ACS880 ideal for cranes, winches, extruders, crushers, and other high- dynamic applications.

Motor Compatibility and System Flexibility

ACS580

ACS580 is well suited for standard industrial induction motors used in stable, process-driven environments. It is a cost-effective solution where performance requirements are clearly defined and unlikely to change significantly over time.

ACS880

ACS880 supports a wider range of motor technologies, including induction and permanent mag- net motors. It allows both open-loop and closed-loop control, enabling easy system expansion and future upgrades without major redesigns.

Energy Efficiency and Regenerative Braking

ACS580

ACS580 includes built-in energy optimization features that reduce losses during partial-load operation. Braking energy is typically handled through braking resistors or internal braking methods, which are sufficient for most general-purpose applications.

ACS880

ACS880 offers regenerative braking options that feed excess braking energy back into the power grid. This significantly improves energy efficiency, reduces heat dissipation, and lowers operating costs in high-inertia and frequently braking systems.

Torque Accuracy and Industrial Applications

ACS580 delivers consistent torque performance for standard industrial processes where load variations are moderate and predictable.

ACS880 provides superior torque accuracy during rapid load changes and low-speed operation. This level of precision directly improves process stability, product quality, and machine lifespan in demanding industrial environments.

| Application Type | Best Fit Drive | Rationale |

|---|---|---|

| Pumps, Fans, Compressors | ACS580 | Simple setup, built-in control logic, excellent energy efficiency. |

| Conveyors, Mixers (Standard Duty) | ACS580 | Reliable vector control, easy commissioning. |

| Cranes, Winches, Extruders | ACS880 | DTC for high torque accuracy and rapid dynamics. |

| High Inertia & Multi-Motor Systems | ACS880 | Regenerative braking and configurable multi-drive networks. |

| Energy-Sensitive Processes | ACS880 (Regenerative) | Minimized energy waste, feedback to grid. |