Home

>

Blog

>

PLC vs. HMI: A Comprehensive Comparison

In industrial automation, PLCs and HMIs are often mentioned together, yet they serve very

different purposes. Whether working with Siemens, Allen–Bradley, ABB, Schneider Electric,

Mitsubishi, or Omron systems, the fundamental principle remains the same: PLCs control

the process, while HMIs communicate it to people.

Understanding this distinction is essential for designing reliable, maintainable, and efficient

automation systems across manufacturing, oil & gas, utilities, and process industries.

What Does a PLC Really Do?

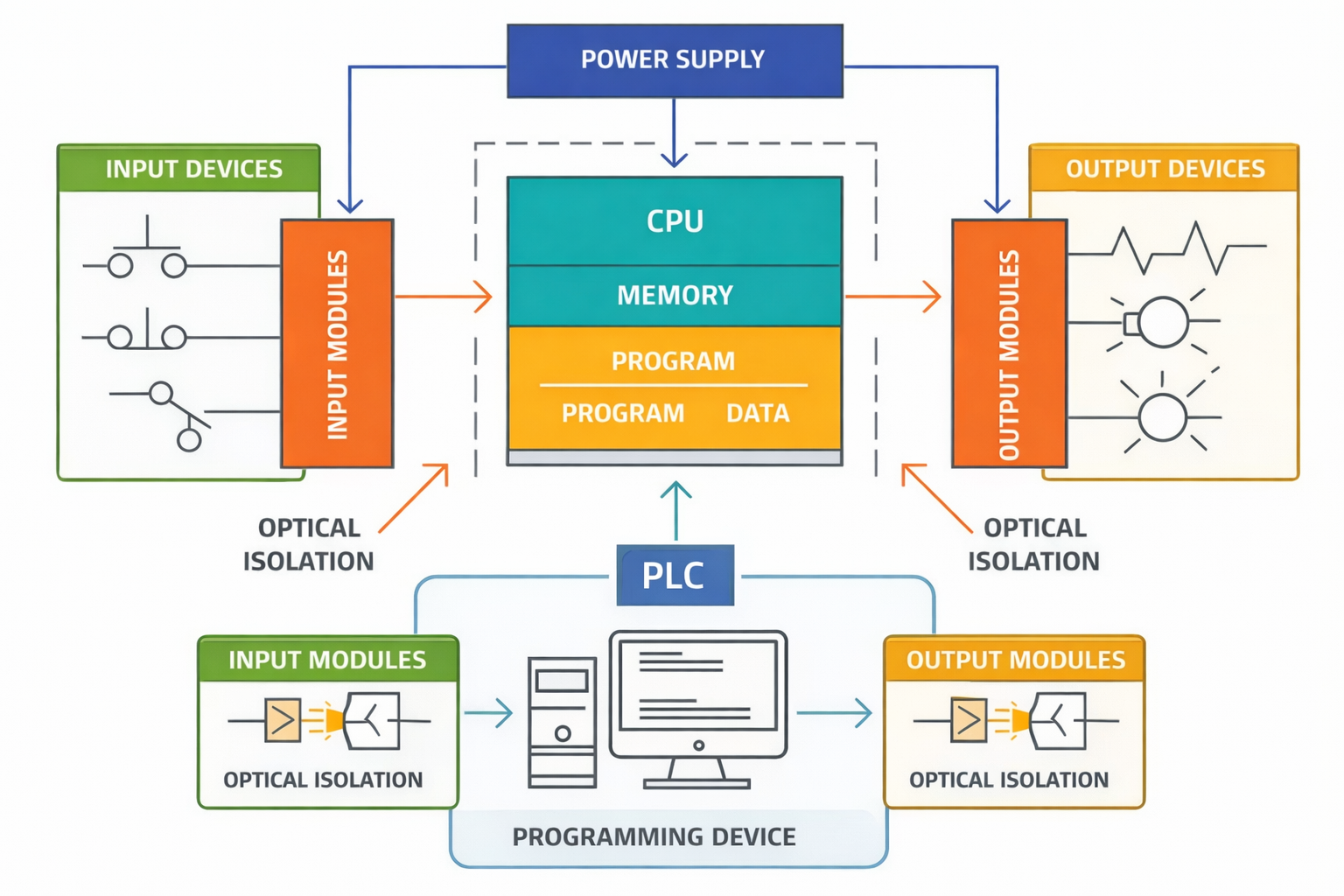

A Programmable Logic Controller (PLC) is the decision–making core of an automation

system.Across all major brands, the PLC is responsible for real–time, deterministic control.

PLCs continuously scan inputs, execute control logic, and update outputs. They handle

motor control, interlocks, sequencing, safety logic, and PID loops while operating reliably in

harsh industrial environments such as high temperatures, vibration, dust, and electrical noise.If

a process must run automatically, safely, and consistently, the PLC is responsible.

Common PLC platforms include

- Siemens S7–1200 / S7–1500

- Allen–Bradley CompactLogix / ControlLogix

- ABB AC500 series

- Schneider Electric Modicon M340 / M580

- Mitsubishi FX / Q series

- Omron CJ / NX series

What Is an HMI and What It Is Not

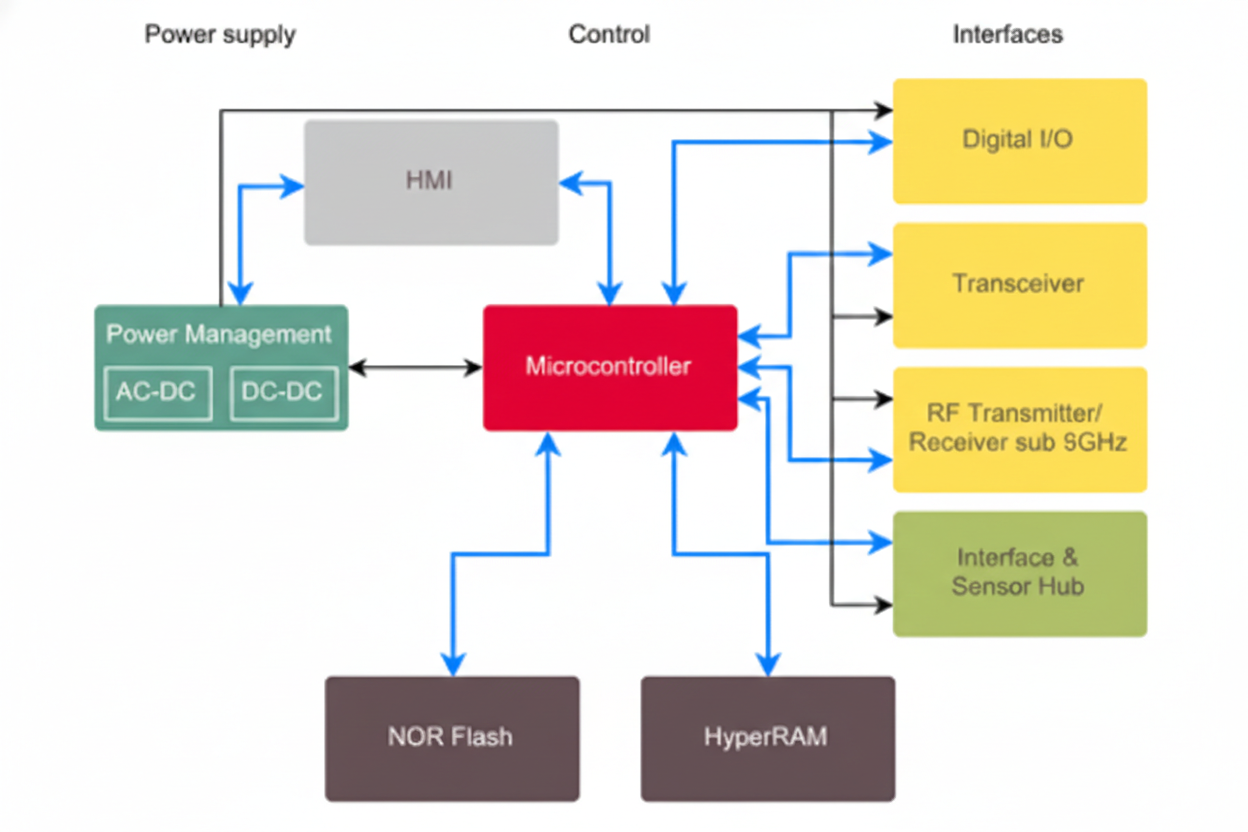

A Human–Machine Interface (HMI) is the visual and interactive layer of the automation system.

HMI does not replace the PLC; instead, it depends on it.HMIs allow operators to monitor process values, view alarms, adjust setpoints, and interact with the system. However, HMIs do

not execute safety logic or make independent control decisions.

Popular HMI platforms include:

- Siemens Comfort and Unified Panels

- Allen–Bradley PanelView Plus

- ABB AC500 series

- Schneider Electric Magelis

- Mitsubishi GOT series

- Omron NB / NA series

Why PLCs and HMIs Work Best Together

In a real industrial setup, PLCs and HMIs are not competitors they’re partners.The PLC does

the thinking. The HMI does the talking.

A well-designed system

- Keeps all control logic inside the PLC

- Uses the HMI only for visualization and operator commands

- Ensures the process remains safe even if the HMI fails

This approach improves reliability and makes maintenance far easier especially in industries

where uptime directly impacts revenue.

Real World Applications

In real installations:

Different brands same proven architecture.

Conclusion

PLCs and HMIs serve different but equally important roles in industrial automation. The PLC

acts as the reliable control engine, while the HMI provides clarity and interaction for human

operators.When designed correctly, they improve system performance, simplify troubleshooting,

and reduce downtime.

Epoch International supports a wide range of PLC and HMI platforms from leading global

brands, offering supply, service, repair, and technical expertise to ensure automation systems

perform reliably in real industrial environments.