Programmable Logic Controller (PLC)

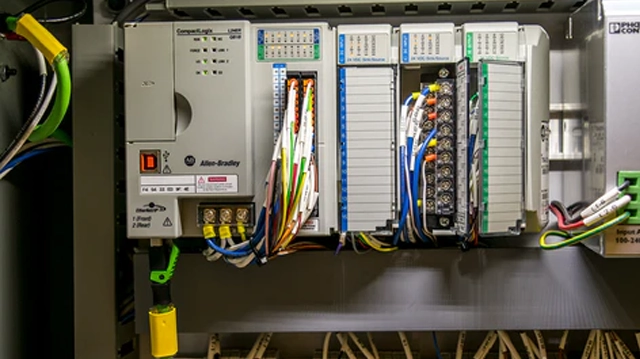

A Programmable Logic Controller is a rugged industrial computer designed for deterministic, high-speed control of machines and processes. PLCs operate reliably in harsh environments involving dust, vibration, electrical noise, and temperature variations. They are programmed using IEC 61131-3 languages such as Ladder Logic, Function Block Diagram, and Structured Text.

PLCs interface directly with digital and analog I/O to control motors, conveyors, valves, robotic systems, and packaging machines. Their modular architecture allows easy expansion and scalability.

Leading PLC Brands and Products

- Siemens SIMATIC S7-1200, S7-1500

- Allen-Bradley ControlLogix and CompactLogix

- Schneider Electric Modicon M340 and M580

- Mitsubishi MELSEC iQ Series

PLCs are widely used in discrete manufacturing industries such as automotive, food pro- cessing, material handling, and CNC machinery.