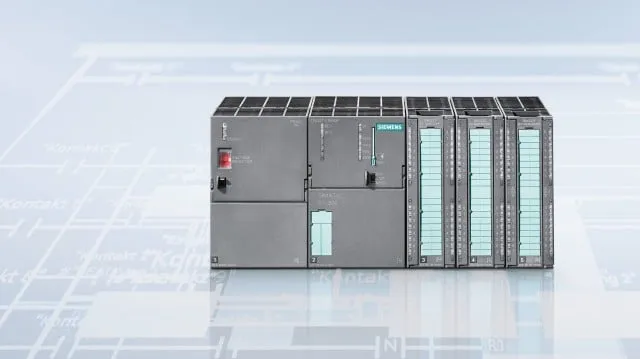

Why Siemens Automation Systems Are Trusted Worldwide

Siemens automation products are not designed as standalone devices. They are engineered as a fully integrated ecosystem, where PLCs, HMIs, and VFDs communicate seamlessly over industrial networks such as PROFINET and PROFIBUS.

This integrated design delivers:

- Faster commissioning

- Simplified diagnostics

- Reduced wiring and engineering effort

- Higher system stability

Sectors such as manufacturing, oil & gas, power generation, water treatment, and pharmaceuticals trust Siemens automation to minimize failures that can cause expensive operational interruptions.