Home

>

Products

>

CNC Machines

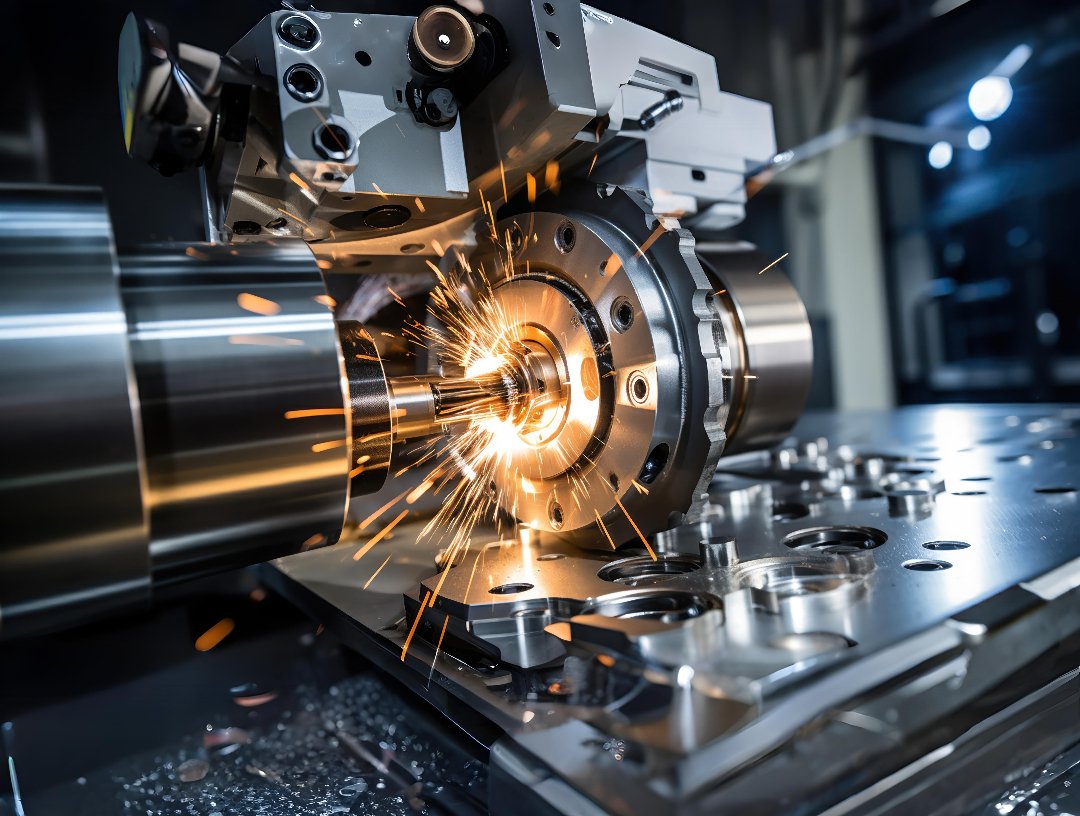

CNC (Computer Numerical Control) machines are at the heart of modern precision manufacturing. From aerospace and automotive to mold-making and electronics, CNC systems drive productivity through accuracy, repeatability, and speed. To further enhance performance and minimize downtime, factory automation is integrated deeply into CNC machine operations. Automation doesn’t just control the machine—it powers the entire workflow around it, from raw material loading to final inspection. Core automation components that optimize CNC systems include PLCs, servo drives, spindle motor controllers, HMIs (Human Machine Interfaces), VFDs (Variable Frequency Drives), and linear encoders. These components ensure smooth axis movements, precise tool control, and high-speed spindle performance. Global brands like Siemens, Mitsubishi Electric, Fanuc, Allen Bradley, Delta, and Omron offer dedicated CNC automation solutions trusted in industries that demand precision at every micrometer. Factory automation around CNC machines extends beyond the machine itself. Robotic arms for automated loading/unloading, conveyor systems, coolant control systems, and automated tool changers are increasingly integrated to reduce manual intervention and increase operational hours. HMIs and SCADA systems allow operators to monitor multiple CNC units, track cycle times, tool wear, and machine diagnostics—all in real-time. Temperature and vibration monitoring are crucial in high-speed machining environments. Sensors and analog input modules like PT100 converters ensure thermal stability and early detection of anomalies. Servo motors and drives ensure fine-tuned control over multi-axis motion systems, enabling intricate operations like 5-axis milling, engraving, or high-precision turning. CNC factories also benefit from predictive maintenance through IIoT-enabled automation. Machine learning algorithms analyze real-time data to schedule maintenance before failure occurs, ensuring maximum uptime. Integration of MES (Manufacturing Execution Systems) enables job scheduling, quality tracking, and workflow optimization—making the entire operation lean and efficient. In sectors like die manufacturing and aerospace, even micro-level errors can lead to costly failures. That’s why automation in CNC machining isn’t just about faster production—it’s about consistency, accuracy, and reliability. Whether you're running a standalone CNC lathe or managing a full-fledged automated machining center, factory automation ensures you get the most out of every rotation, cut, and pass.